I visited the Lotus Cars factory in Hethel, Norfolk, to discover the production of the latest sports car, the Emira. The Emira is set out to be the last Lotus to be powered by non-hybrid combustion engine.

The Lotus Emira is a much more user-friendly sports car compared to previous Lotus-es – the access to the cabin has been improved significantly over the Elise or the Exige by lowering the door sill. Interesting findings about the Lotus Emira:

- The Toyota engine and transmission are heavily reworked to make it compatible with the Emira.

- The AMG engine requires external electro-hydraulic pump for steering rack. AMG vehicle have an electric-only steering rack, but Lotus add the new pump to increase the level of steering wheel feel.

- The V6 Toyota engine has got visible pressure release valve in engine bay.

Production line interesting discoveries:

- Production is based on a 4-day working week, but keeps the standard 40 working hours. Advantage is that Friday’s are still available if the production is required to catch-up.

- The Emira has got a tact time of 17 min: every 17 minutes, a Lotus Emira rolls off the production line. If one bay fails, the vehicle continues the build process and the missing part is fitted additionally at the end of the process.

- The production line is not a conveyor belt, but on ATVs (autonomous transport vehicles) – this shows the technical innovations at Lotus.

- To increase the quality of the end product, the cars are audit-ed midway through the production process: once the body panels are bolted onto the chassis, the car is CMM’ed to ensure alignment. If misalignment is detected by the CMM, a “jig cube” is used to determine if the body panels or if the chassis itself are not straight.

- The only robot-assembled parts on the Emira are the A-pillars to the roof. The remainder of the vehicle is hand-built.

- The majority of the body panels are bolted onto the aluminium centre shell and the aluminium front and rear subframes. The centre shell is manufactured from bonded aluminium. Body panels are painted separately and then bolted on manually.

The Lotus Evija was being produced in a building next to the Lotus Emira. The 3rd Lotus car, the Electre electric SUV is being produced in Wuhan, China. In the upcoming years, Lotus shall release an electric sports car which will replace the Emira. In addition, an electric sedan will also be released to complete the Lotus portfolio.

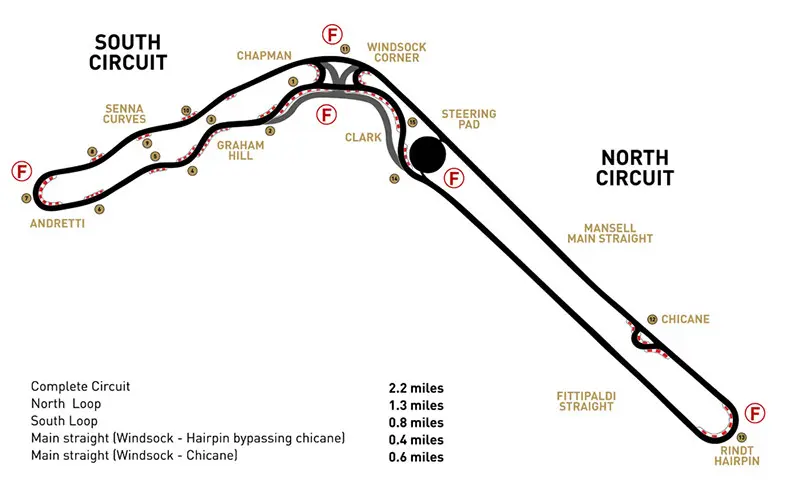

The Lotus factory in Hethel also features a private test track, with straights and corners bearing some very important names.

Conclusion

All in all, I loved my visit at Lotus Cars. I highly recommend it to any car enthusiast that wishes to discover more about this manufacturer. Lotus is a prosperous company and is becoming an increasingly important competitor in the luxury and sports car market.